- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

CGF8-8-3

MARS

842230

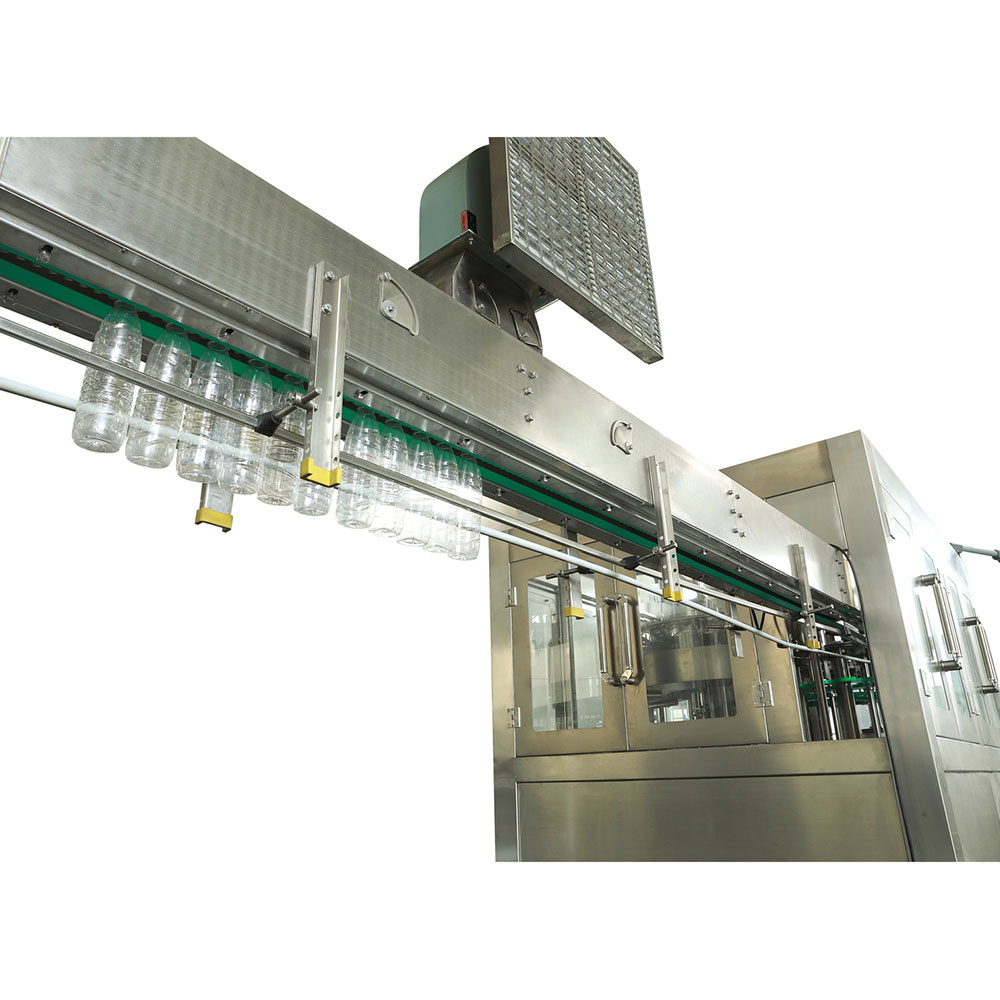

The 8/8/3 Automatic Small Scale Mineral Water Bottle Filling Bottling Machine is designed for high-efficiency water production lines. It integrates bottle washing, filling, and capping in one compact unit. This machine offers flexibility in bottle sizes, accommodating a wide range of diameters and heights.

With its precise filling valve, the machine ensures accurate liquid levels, minimizing waste. The equipment’s high-speed operation increases production output, while the constant torque capping device guarantees high-quality seals. It is suitable for filling plastic screw cap bottles.

This machine operates with a clean management system to maintain bottle cleanliness throughout the production process. The adjustable frequency converter enables smooth operation and energy-saving features. It is compatible with various production lines, making it an ideal choice for beverage manufacturers looking for efficiency and flexibility.

The CGF8-8-3 model is designed for small-scale production, handling up to 2,500 bottles per hour (based on 500ml bottles). It offers a cost-effective solution for manufacturers and suppliers in need of an automated bottling process.

Model | CGF8-8-3 |

Production capacity | 2,000-2,500B/H(basis on 500ml bottle) |

Filling precision | ≤±3mm(liquid level) |

| Suitable bottle diameter | 50-105mm |

| Suitable bottle height | 150-340mm |

Suitable cap type | plastic screw cap |

Water pressure of washing bottle | 0.18-0.25Mpa |

Water consumption for washing bottle | 800Kg/h |

Spraying position | 2 |

Dripping bottle position | 2 |

Gas source pressure | 0.4Mpa |

Gas consumption | 0.4m3/min |

Total power | 3.73Kw |

Overall dimension | 1850×1500×2000mm |

Total weight | 2400Kg |

Compact Structure & Automation: Offers easy operation with a high level of automation for efficiency.

Anti-Corrosive SUS Materials: Parts in contact with the product are made of SUS, ensuring durability and easy cleaning.

High-Speed Filling Valve: Guarantees precise liquid level control, minimizing waste during the filling process.

Constant Torque Capping: Magnetic device ensures high-quality capping and prevents cap damage during the process.

Efficient Cap Arranging System: Features a high-efficiency system with perfect cap feeding and protection.

Clean Management System: Effectively maintains bottle cleanliness throughout the production process.

Adjustable Bottle Shape: Easily change bottle sizes by adjusting the star-wheel for different shapes.

Overload Protection Device: Ensures operator and machine safety by preventing overload situations.

Adjustable Frequency Converter: Ensures smooth operation by allowing flexible adjustments in speed.

Imported Electrical & Pneumatic Components: Uses high-quality components for reliable performance and durability.

Advanced Control System: Offers functions like speed control, cap shortage detection, automatic stop, and production counting.

High Automation: Minimal human intervention, making operation simple and efficient.

Quality Materials: Durable components that are easy to clean, ensuring long-term reliability.

Precise Filling and Capping: Guarantees consistency in product quality with exact filling and capping.

Flexible Bottle Handling: Easily adjustable to handle various bottle shapes without extra effort.

Enhanced Safety: Overload protection and high-quality electric components ensure safe operation.

High Efficiency: The efficient cap feeding and arranging system maintains smooth production flow.

Beverage Industry: Perfect for filling and capping pure water, mineral water, and other liquid beverages.

Small-Scale Production: Ideal for smaller-scale water bottling operations needing flexibility and efficiency.

Installation Support: Mars Packing Machinery offers full support for smooth installation and setup.

Training: Operational training to ensure staff can use the machine effectively.

Aftermarket Support: Continuous technical support and spare parts availability for ongoing maintenance.

Customization: Machines can be customized to meet specific production needs and requirements.

Mars Packing Machinery specializes in the production of high-quality filling and bottling machines for the beverage industry. With years of experience, the company focuses on delivering reliable, efficient, and cost-effective solutions that meet global industry standards.

1. What types of bottles are compatible with the 8/8/3 Automatic Filling Machine?

The 8/8/3 Automatic Small Scale Mineral Water Bottle Filling Bottling Machine is compatible with bottles ranging from 50mm to 105mm in diameter and 150mm to 340mm in height. It works well with plastic screw caps and can handle different bottle shapes.

2. What is the production capacity of this machine?

This machine offers a production capacity of 2,000-2,500 bottles per hour, based on a 500ml bottle. This makes it ideal for small-scale water bottling operations.

3. How accurate is the filling process?

The machine has a high filling precision, with a liquid level accuracy of ≤±3mm, ensuring consistent and reliable filling.

4. How does the machine ensure bottle cleanliness?

The machine is equipped with an effective clean management system that ensures all bottles are thoroughly cleaned before filling, using a water pressure range of 0.18-0.25Mpa for bottle washing.

5. Can this machine be customized for specific production needs?

Yes, Mars Packing Machinery offers customization options to meet the unique requirements of your production line, such as adjusting the machine for different bottle shapes or sizes.